Complete Guide to Door & Window Energy Efficiency: Ratings, Standards & 3D Configuration

Master door and window energy efficiency with comprehensive guide to ENERGY STAR ratings, NFRC standards, U-factors, and 3D configuration for optimal performance and cost savings.

Jennifer Martinez

Introduction: The Critical Role of Energy Efficiency in Doors and Windows

Doors and windows are among the most significant factors affecting a building's energy performance, accounting for up to 30% of heating and cooling energy use in residential buildings and even more in commercial structures. With rising energy costs and increasing environmental awareness, understanding and optimizing door and window energy efficiency has become essential for builders, architects, and property owners.

Modern 3D configuration technology is revolutionizing how we select, specify, and optimize doors and windows for energy performance. This comprehensive guide explores energy efficiency standards, rating systems, and how advanced configuration tools can help achieve optimal performance while meeting aesthetic and functional requirements.

Understanding Energy Efficiency Fundamentals

Energy efficiency in doors and windows involves multiple factors that work together to minimize heat transfer and air infiltration:

Heat Transfer Mechanisms

- Conduction: Heat transfer through solid materials like frames and glass

- Convection: Heat transfer through air movement and circulation

- Radiation: Heat transfer through electromagnetic waves, particularly solar radiation

- Air Infiltration: Unwanted air leakage through gaps and seals

Key Performance Metrics

- U-Factor: Overall heat transfer coefficient (lower is better)

- Solar Heat Gain Coefficient (SHGC): Fraction of solar radiation admitted

- Visible Transmittance (VT): Fraction of visible light transmitted

- Air Leakage: Rate of air infiltration through the assembly

- Condensation Resistance: Ability to resist condensation formation

ENERGY STAR and NFRC Rating Systems

Understanding rating systems is crucial for making informed decisions about door and window energy performance:

ENERGY STAR Program

ENERGY STAR provides simplified efficiency criteria based on climate zones:

- Northern Climate: U-Factor ≤ 0.30, any SHGC

- North-Central Climate: U-Factor ≤ 0.30, SHGC ≤ 0.40

- South-Central Climate: U-Factor ≤ 0.30, SHGC ≤ 0.25

- Southern Climate: U-Factor ≤ 0.65, SHGC ≤ 0.25

NFRC (National Fenestration Rating Council)

NFRC provides detailed, standardized testing and rating procedures:

- Standardized Testing: Consistent testing conditions and procedures

- Whole Product Rating: Performance of complete window or door assembly

- Independent Verification: Third-party testing and certification

- Detailed Reporting: Comprehensive performance data

Understanding U-Factor in Detail

U-Factor is the most important metric for energy efficiency:

- Definition: Rate of heat transfer through the entire assembly

- Units: Btu/hr·ft²·°F (lower numbers indicate better insulation)

- Typical Ranges: 0.20-0.80 for windows, 0.15-0.50 for doors

- Climate Considerations: More critical in heating-dominated climates

Window Energy Efficiency Technologies

Modern windows incorporate multiple technologies to achieve high energy performance:

Glazing Technologies

- Low-E Coatings: Microscopic metallic coatings that reflect infrared radiation

- Multiple Panes: Double and triple-pane configurations for enhanced insulation

- Gas Fills: Argon and krypton gas between panes for better insulation

- Warm Edge Spacers: Insulating spacers that reduce edge heat transfer

- Spectrally Selective Glazing: Coatings that optimize light transmission

Frame Materials and Design

- Vinyl Frames: Good insulation, low maintenance, cost-effective

- Fiberglass Frames: Excellent insulation, dimensional stability

- Wood Frames: Natural insulation, aesthetic appeal, requires maintenance

- Aluminum Frames: Durable but requires thermal breaks for efficiency

- Composite Frames: Engineered materials combining multiple benefits

Advanced Window Technologies

- Dynamic Glazing: Electrochromic and thermochromic glass

- Vacuum Glazing: Ultra-thin insulating glass units

- Aerogel Glazing: Transparent insulation materials

- Photovoltaic Integration: Solar cells integrated into glazing

Door Energy Efficiency Considerations

Doors present unique energy efficiency challenges and opportunities:

Door Construction Types

- Solid Wood: Traditional construction with moderate insulation

- Engineered Wood: Composite construction with enhanced stability

- Steel: Durable with foam core insulation options

- Fiberglass: Excellent insulation and weather resistance

- Aluminum: Commercial applications with thermal breaks

Insulation Strategies

- Foam Core: Polyurethane foam injection for maximum R-value

- Honeycomb Core: Lightweight insulation with good performance

- Mineral Wool: Fire-resistant insulation option

- Vacuum Panels: Ultra-high performance insulation

Glazing in Doors

- Glass Area Optimization: Balancing light and energy performance

- Glazing Technologies: Same principles as windows apply

- Frame Integration: Thermal bridging considerations

- Security Considerations: Impact on glazing selection

Climate Zone Considerations

Energy efficiency requirements vary significantly by climate zone:

Heating-Dominated Climates (Zones 1-4)

- Priority: Minimize heat loss through low U-factors

- Solar Gain: Moderate to high SHGC can be beneficial

- Orientation: South-facing windows for passive solar heating

- Air Sealing: Critical for preventing infiltration losses

Cooling-Dominated Climates (Zones 7-8)

- Priority: Minimize solar heat gain through low SHGC

- U-Factor: Less critical but still important

- Shading: External shading strategies crucial

- Ventilation: Natural ventilation opportunities

Mixed Climates (Zones 5-6)

- Balance: Optimize for both heating and cooling seasons

- Orientation-Specific: Different strategies for different exposures

- Seasonal Controls: Operable shading and ventilation

- Thermal Mass: Integration with building thermal mass

3D Configuration for Energy Optimization

Modern 3D configuration tools enable sophisticated energy performance optimization:

Performance Modeling Integration

- Real-Time Calculations: Instant energy performance feedback

- Climate Data Integration: Location-specific performance predictions

- Whole Building Analysis: Integration with building energy models

- Optimization Algorithms: Automated optimization for performance targets

Configuration Parameters

- Glazing Selection: Interactive comparison of glazing options

- Frame Materials: Performance and cost trade-offs

- Size Optimization: Balancing light, views, and energy performance

- Orientation Analysis: Performance by building orientation

Visualization Capabilities

- Performance Mapping: Visual representation of energy flows

- Comfort Analysis: Thermal comfort and glare visualization

- Seasonal Variations: Performance throughout the year

- Comparative Analysis: Side-by-side option comparisons

Cost-Benefit Analysis of Energy Efficiency

Understanding the financial implications of energy efficiency investments:

Initial Cost Considerations

- Premium Pricing: High-performance products cost 10-30% more

- Installation Complexity: Some products require specialized installation

- Design Integration: Coordination with other building systems

- Certification Costs: Third-party testing and verification

Operating Cost Savings

- Energy Savings: 15-30% reduction in heating/cooling costs

- Peak Demand Reduction: Lower utility demand charges

- Maintenance Savings: Reduced HVAC system wear

- Comfort Improvements: Reduced hot/cold spots and drafts

Payback Period Analysis

- Simple Payback: Typically 5-15 years for premium windows

- Net Present Value: Accounting for energy cost escalation

- Utility Incentives: Rebates and tax credits reduce payback

- Property Value: Increased resale value considerations

Installation and Quality Assurance

Proper installation is crucial for achieving rated energy performance:

Installation Best Practices

- Air Sealing: Continuous air barrier around openings

- Thermal Bridging: Minimizing conductive heat transfer paths

- Flashing Details: Proper water management integration

- Structural Integration: Proper load transfer and support

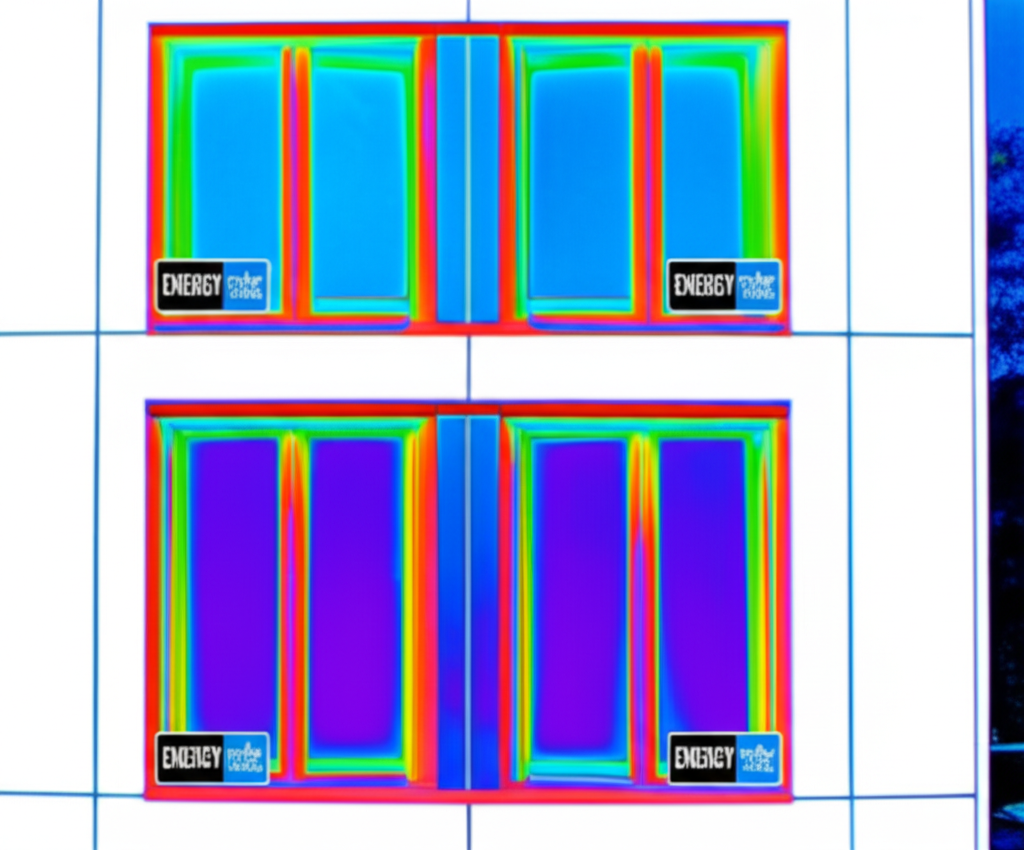

Quality Control Measures

- Blower Door Testing: Verification of air sealing performance

- Thermal Imaging: Detection of thermal bridging and air leaks

- Performance Testing: Field verification of energy performance

- Documentation: Proper record keeping for warranties

Common Installation Issues

- Air Leakage: Inadequate sealing around frames

- Thermal Bridging: Conductive paths through installation

- Moisture Problems: Improper flashing and drainage

- Structural Issues: Inadequate support and fastening

Maintenance for Long-Term Performance

Maintaining energy efficiency over the product lifecycle:

Preventive Maintenance

- Seal Inspection: Regular checking of weatherstripping and caulking

- Hardware Maintenance: Lubrication and adjustment of moving parts

- Glass Cleaning: Maintaining optimal light transmission

- Frame Care: Material-specific maintenance requirements

Performance Monitoring

- Energy Monitoring: Tracking building energy performance

- Comfort Complaints: Identifying performance degradation

- Visual Inspection: Regular assessment of condition

- Professional Assessment: Periodic expert evaluation

Upgrade Opportunities

- Retrofit Options: Improving existing installations

- Technology Updates: Incorporating new technologies

- System Integration: Connecting with smart building systems

- Performance Optimization: Fine-tuning for changing needs

Future Trends in Door and Window Energy Efficiency

Emerging technologies and trends shaping the future:

Smart and Dynamic Systems

- Automated Controls: Responsive shading and ventilation systems

- Sensor Integration: Real-time environmental monitoring

- Machine Learning: Predictive optimization algorithms

- IoT Connectivity: Integration with building management systems

Advanced Materials

- Phase Change Materials: Thermal energy storage in frames

- Aerogel Insulation: Ultra-high performance transparent insulation

- Biomimetic Materials: Nature-inspired efficiency solutions

- Recyclable Materials: Sustainable high-performance options

Manufacturing Innovations

- 3D Printing: Custom components and complex geometries

- Automated Assembly: Precision manufacturing for better performance

- Quality Control: Advanced testing and verification methods

- Mass Customization: Efficient production of custom solutions

Regulatory and Code Considerations

Understanding the regulatory landscape for energy efficiency:

Building Energy Codes

- IECC (International Energy Conservation Code): Model energy code

- State Codes: State-specific energy requirements

- Local Amendments: Municipal modifications and additions

- Compliance Paths: Prescriptive vs. performance-based compliance

Green Building Standards

- LEED: Leadership in Energy and Environmental Design

- ENERGY STAR: EPA voluntary program

- Passive House: Ultra-low energy building standard

- Living Building Challenge: Regenerative building standard

Incentive Programs

- Federal Tax Credits: Residential and commercial incentives

- Utility Rebates: Local utility efficiency programs

- State Programs: State-specific incentives and rebates

- Financing Programs: PACE and other financing options

Implementation Strategies for Professionals

Practical guidance for architects, builders, and specifiers:

Design Process Integration

- Early Planning: Energy considerations from project inception

- Integrated Design: Coordination with all building systems

- Performance Targets: Setting and tracking energy goals

- Value Engineering: Optimizing performance vs. cost

Product Selection Process

- Performance Requirements: Defining minimum performance criteria

- Comparative Analysis: Systematic evaluation of options

- Life Cycle Assessment: Long-term performance and cost analysis

- Risk Assessment: Evaluating performance and durability risks

Quality Assurance Programs

- Specification Development: Clear, enforceable specifications

- Contractor Training: Ensuring proper installation practices

- Inspection Protocols: Systematic quality verification

- Performance Verification: Post-installation testing and commissioning

Case Studies and Real-World Applications

Learning from successful energy efficiency implementations:

Residential Case Study: Net-Zero Home

- Project Overview: 2,500 sq ft custom home in Climate Zone 5

- Window Strategy: Triple-pane, U-0.18, SHGC-0.25 windows

- Door Selection: Fiberglass entry doors with U-0.15 rating

- Results: 45% reduction in heating/cooling energy use

- Cost Premium: 12% increase in window/door costs

- Payback Period: 8 years with utility incentives

Commercial Case Study: Office Building Retrofit

- Project Overview: 50,000 sq ft office building renovation

- Challenge: Aging single-pane windows with high energy costs

- Solution: High-performance curtain wall system

- Performance: U-0.25, SHGC-0.30 with automated shading

- Results: 35% reduction in HVAC energy use

- Additional Benefits: Improved comfort and productivity

Institutional Case Study: School District

- Project Overview: District-wide window replacement program

- Standardization: Common specifications across all schools

- Performance Requirements: ENERGY STAR certification minimum

- Procurement Strategy: Volume purchasing for cost savings

- Results: 25% reduction in district energy costs

- Educational Value: Teaching tool for energy awareness

Conclusion: The Future of Energy-Efficient Doors and Windows

Energy efficiency in doors and windows has evolved from a niche consideration to a fundamental requirement for responsible building design and construction. The combination of advanced materials, sophisticated rating systems, and intelligent configuration tools enables unprecedented levels of performance optimization.

The key to success lies in understanding the complex interplay between climate, building design, occupant needs, and economic constraints. Modern 3D configuration tools make this complexity manageable by providing real-time feedback on performance and cost implications of different choices.

As building energy codes become more stringent and energy costs continue to rise, the importance of high-performance doors and windows will only increase. The professionals who master these technologies and integrate them effectively into their design and construction processes will be best positioned to deliver superior value to their clients while contributing to a more sustainable built environment.

The future promises even more sophisticated solutions, with smart materials, dynamic systems, and AI-driven optimization creating new possibilities for energy performance. By staying informed about these developments and investing in the tools and knowledge needed to implement them effectively, building professionals can ensure they remain at the forefront of this rapidly evolving field.

Tags

Jennifer Martinez

Expert in door and window energy efficiency, building performance, and sustainable construction technologies. Helping builders and architects optimize building envelope performance.